Alloys

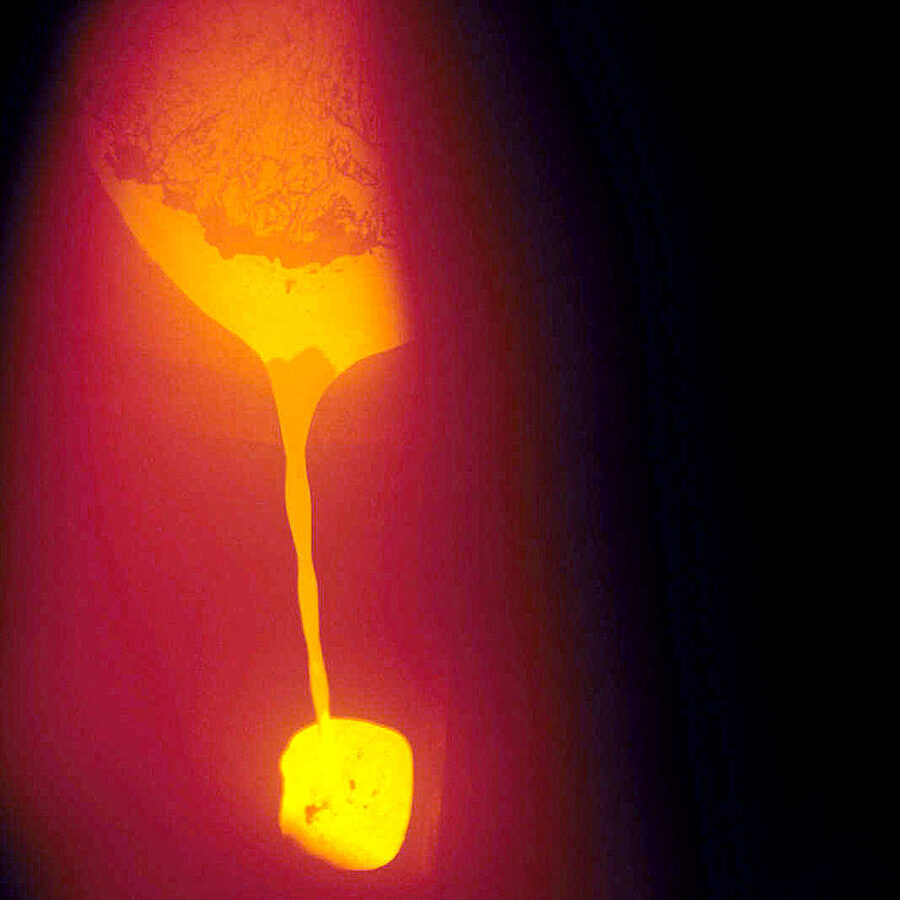

The basic materials for all alloys are pure metals such as copper, nickel, cobalt, chromium, beryllium and zircon. These metals are prepared in correct quantities and filled into the crucible of the vacuum furnace. Recharging during the melting process is carried out via a lock chamber. Once the melting process being finished, the alloy is cast under vacuum into one or several moulds. Due to this procedure under complete absence of air, a very high purity and quality of the alloy are achieved. Negative environmental influences are completely excluded.

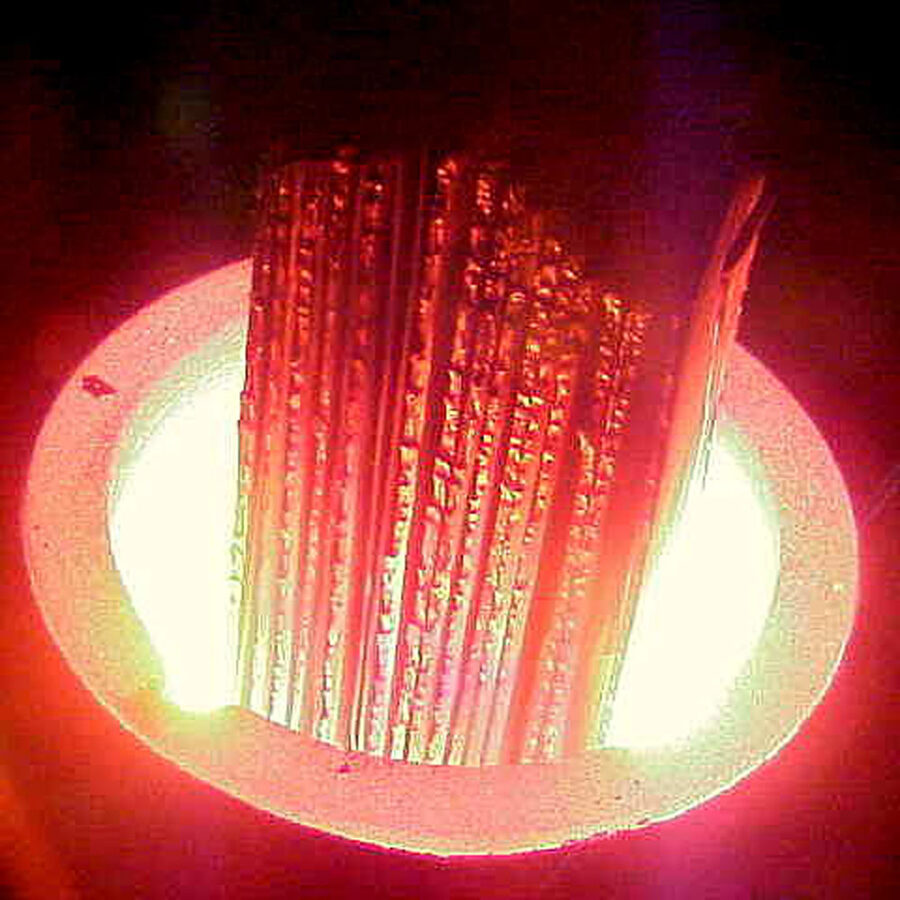

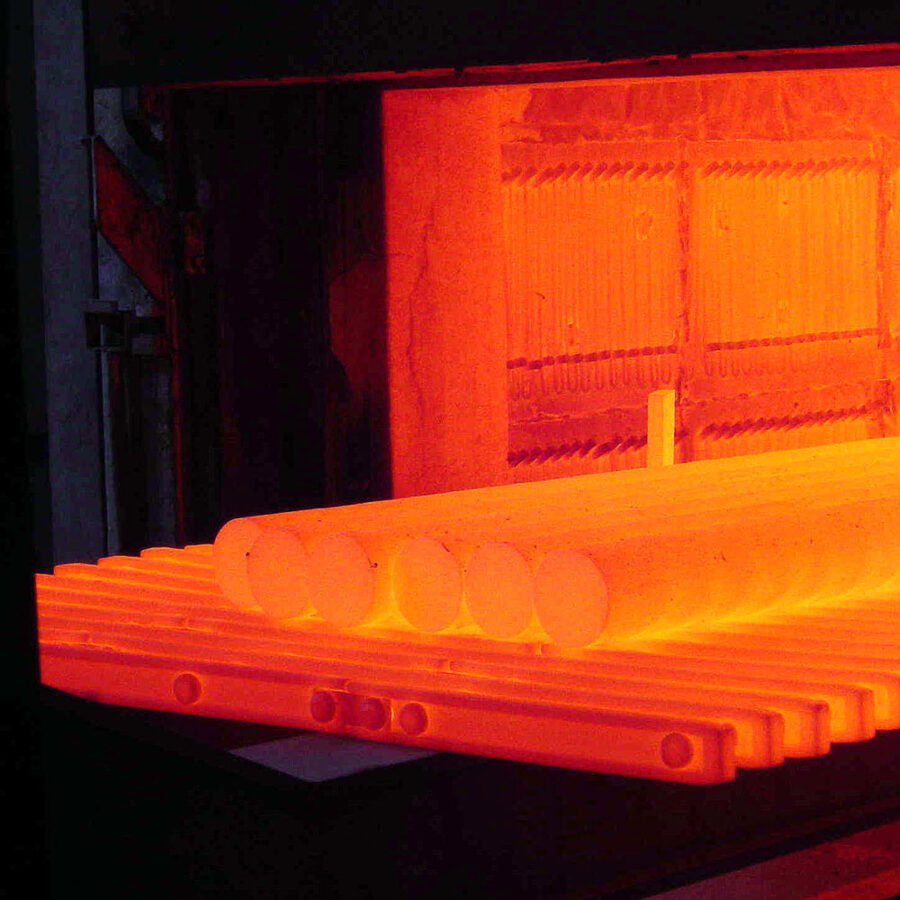

Our partners process the ingots into semi-finished products through forging, rolling, extruding and drawing. The processing is followed by a heat treatment which is necessary to achieve the required properties, such as hardness, electrical conductivity, thermal conductivity.